£3-M investment in 3D printing to double Bentley parts production capacity

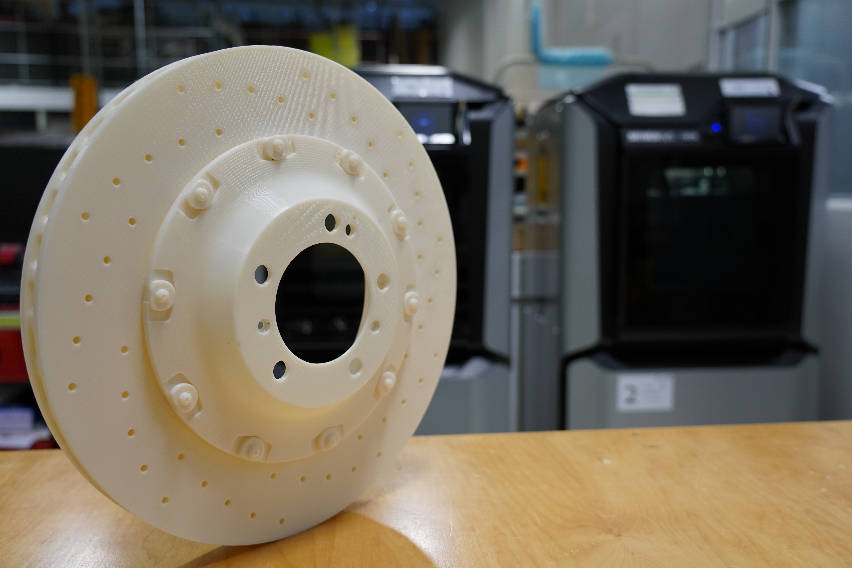

Bentley Motors has invested £3 million in its manufacturing factory to double its 3D printing capacity. According to the British luxury car brand, the recent funding its Crewe facility received allowed for the construction of a state-of-the-art 3D printing facility which in 2021 alone produced 15,000 components.

KEY TAKEAWAYS

How much is Bentley investing in 3D printing?

Bentley is investing £3 million.How many components did Bentley print in 2021?

Last year, Bentley printed 15,000 components.The brand’s research and development team said they have already identified a wide variety of components that can be printed which can significantly expand Bentley’s capabilities of providing its customers even greater level of personalization.

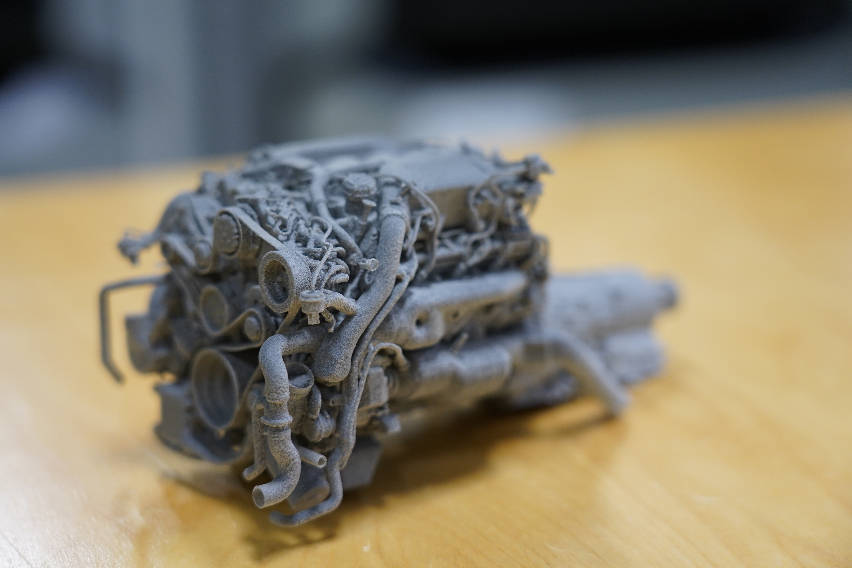

Bentley has used 3D printing technology in various projects including building prototypes such as powertrain and aerodynamic wind tunnel models. The technology has also been applied in producing parts for Bentley models that were driven in the demanding Pikes Peak Challenge in America.

In addition to giving the brand almost limitless possibilities in producing a wide variety of parts and models, Bentley’s £3-million investment also has an environmental impact. The new equipment and manufacturing process used in 3D printing reduces waste and saves on development time. Bentley said that its equipment can cut half of the production cost by saving on parts and by operating around the clock with the facility capable of producing thousands of components in over 25 different material options.

“Bentley’s approach to additive manufacturing is industry-leading and the facility is quickly becoming a cornerstone of our ‘Dream Factory’ ambitions. One of the key benefits is that it is efficiency-led, cutting down on the cost and complexity of a myriad of jobs,” said Bentley Member of the Board for Manufacturing Peter Bosch.

“This latest investment is also making a significant impact with our colleagues from across the company, helping to create advanced assisted tools to drive continuous improvement throughout manufacturing processes. As we look to the future, there really is huge potential to where this advanced technology can progress, including having a greater ability to personalize parts for our customers and further enhancing the individualization program offered on every car,” added Bosch.

Photos from Bentley

Also read:

Bentley secures production of first BEV, commits to £2.5-B sustainability investment

Bentley Flying Spur Hybrid makes European debut at 2022 Autoworld

Bentley sales grow by 31% in 2021 with increased demand for hybrid models

Featured Articles

- Latest

- Popular

Recommended Articles For You

Featured Bentley Cars

- Popular

Bentley Car Articles From Zigwheels

- News