Lamborghini discusses supply chain challenges, prospects

Lamborghini issued a press release revealing the company’s take on the supply chain challenges faced by the automotive industry and its prospects.

KEY TAKEAWAYS

What is Lamborghini's strategy to ensure the constant movement of its supply chain?

According to Chief Procurement Officer Silvano Michieli, Lamborghini takes risk limitation measures such as going for a more traditional supplier-client relationship with its partners.Does being part of the Volkswagen Group give Lamborghini any advantage?

Per Michieli, Lamborghini benefits from being a part of the VW Group in a way that the brand is prioritized when it comes to supplies.What is the biggest challenge that Lamborghini sees in the future as an automobile maker?

Lamborghini said that irregularities in the supply of core materials and components are the biggest risks an automotive company could face.Since 2020, global supply chains have encountered exceptional political, social, and economic circumstances due to the COVID-19 pandemic, the semiconductor shortage, and the war between Russia and Ukraine. Despite these challenges, the Italian carmaker remained strong and resilient as Lamborghini did not only take on these challenges but also achieved record-breaking results on the sales and financial fronts.

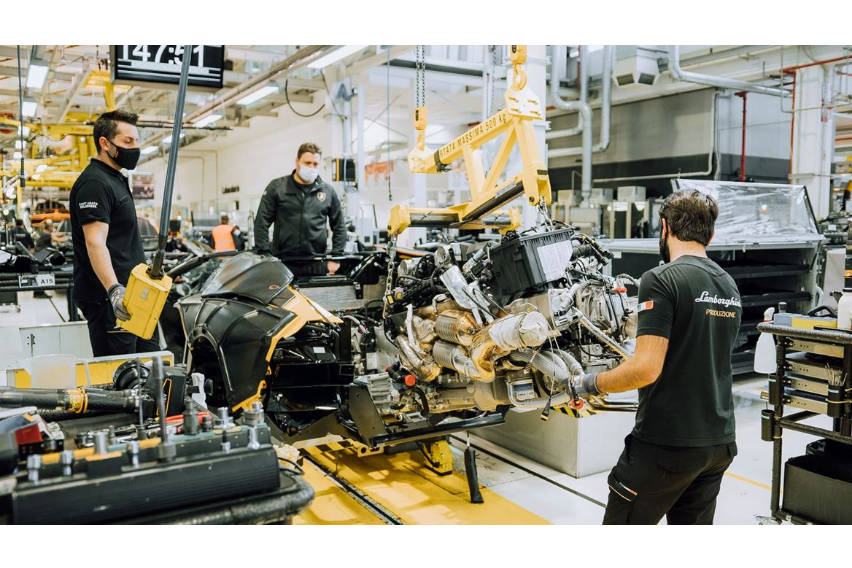

The Sant'Agata Bolognese-based company reveals the strategies it used to ensure that production could continue uninterrupted and the approach it is taking as it prepares for the future.

“First COVID, then the issue with semiconductors, not to mention the conflict in Ukraine and protectionist policies. Against this backdrop, Lamborghini has been taking risk limitation measures and securing its supply chain. One of the main initiatives that we’ve taken here has been to forge even closer ties with some of our strategic suppliers, going from a more traditional ‘supplier-client’ relationship to one that’s more of a partnership,” explained Lamborghini Chief Procurement Officer Silvano Michieli.

“At the same time, we revise our processes to a more proactive, analytical approach. This will enable us to anticipate any new problems in the industry. Now more than ever, we firmly believe that it’s essential to take a problem-solving approach in an international environment that will present more and more challenges and difficulties,” he added.

Lamborghini works closely with its partners in Ukraine such as Leoni, a company that produces wiring for the Huracán in the West of the country. The Volkswagen Group, which Lamborghini is a part of, has established an emergency task force that is responsible for ensuring that a steady flow of supplies continues to arrive.

“Leoni’s staff are having to make huge sacrifices to keep their manufacturing processes moving and thus keep driving the production capacity of their country. The time they spend working is interspersed with curfew periods when they have to take shelter in the underground areas of the production plant. They show heroic amounts of courage, devotion to their work, and love for their country, and Lamborghini is enormously grateful to them,” said Michieli.

Should Leoni’s production come to a halt, Lamborghini looks to apply a “dual production” strategy.

“Thanks to our help, our Ukraine-based suppliers are working to ensure that some of their plants in Europe can count on the same production capabilities. It means that our relationship with our established suppliers will remain unchanged. They’ll continue their production work in the factory in Ukraine while we support the process of duplicating the plant outside the theater of war. Although we hope it doesn’t happen, we’ll be ready if the war brings production in Ukraine to a halt again. It’s a way of showing our trust and gratitude to the staff on our supply chain in Ukraine, who strive to keep production going every day,” shared the Lamborghini CPO.

Lamborghini is also pretty confident in its ability to continue its cadence in terms of production, thanks to its parent conglomerate, the Volkswagen Group.

“There are considerable advantages to being part of a group like Volkswagen and this is demonstrated by situations such as the semiconductor shortage. Lamborghini has one of the highest contribution margins in the group, so it is prioritized when it comes to supplies. In addition, the group gives us access to a number of forms of technology that play a crucial role in our evolution. We’re talking about technology that would not normally be within reach of a small company like ours. It gives us exclusive access to innovative solutions and a clear competitive edge over our rivals,” Michieli said.

Today, Lamborghini is in the process of reorganizing its stock management as the Italian luxury sports car maker has come to realize that irregularities in the supply of core materials and components, which play the most decisive role in the whole production cycle, are the biggest risks an automotive company could face.

Looking toward the future of the company, Michieli shares his take on globalization.

He said, “I think that phenomena like globalization are irreversible. Numerous geographical areas contribute to the production cycles of items that are made today. In my opinion, an extreme form of deglobalization is a utopian, short-sighted idea. I’m more of a believer in rethinking the current supply processes and outlooks, which are in any case undergoing a natural evolution in the industry due to the new circumstances.”

Photos from Lamborghini

Also read:

Fancy a Lamborghini scented candle?

Featured Articles

- Latest

- Popular

Recommended Articles For You

Featured Lamborghini Cars

- Popular

Lamborghini Car Articles From Zigwheels

- News

- Article Feature